Graphite Gaskets: A Complete Guide to High-Performance Industrial Sealing

Industrial systems operating under extreme temperatures, aggressive chemicals, and high-pressure media require a sealing material that can withstand the toughest environments. Graphite gaskets are designed precisely for this purpose. Their exceptional heat resistance, chemical stability, and sealing performance make them a preferred choice across oil & gas, chemical industries, power plants, boilers, and refineries.

As a leading manufacturer and supplier, CRI Gasket provides premium-quality graphite gaskets engineered for long-term durability and reliability.

This comprehensive guide covers everything you need to know about graphite gaskets from types and uses to key advantages and selection criteria.

What Is a Graphite Gasket?

A graphite gasket is a sealing material made from pure, expanded, or laminated graphite. It is known for its exceptional ability to withstand extreme temperatures (up to 450°C–650°C and beyond with reinforcement), high pressure, and aggressive chemicals.

Graphite’s unique layered structure provides:

High compressibility

Excellent recovery

Thermal stability

Chemical resistance

Long sealing life

This makes graphite gaskets ideal for environments where rubber, PTFE, or metal gaskets fail.

Why Graphite? The Science Behind Its Performance

Graphite is a crystalline form of carbon with a natural ability to resist:

High temperatures

High pressure

Thermal shock

Oxidation (when treated)

Corrosive media

Its layered sheet-like structure allows it to compress easily and form a tight seal under pressure, without losing flexibility or resilience.

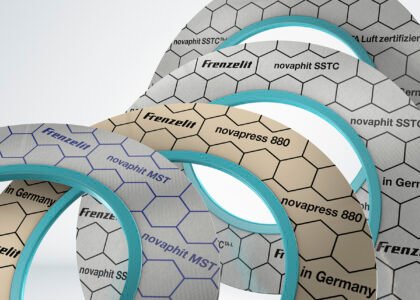

Types of Graphite Gaskets

Industries use various kinds of graphite-based gaskets depending on the application and sealing requirements.

1. Pure Graphite Gaskets

Made from 98–99% pure graphite sheets.

Features:

High thermal stability

Ultra-low under-load creep

Excellent leak resistance

Compressible and flexible

Used in flanges, heat exchangers, and equipment with thermal cycling.

2. Reinforced Graphite Gaskets (Tanged / Flat foil)

These gaskets have a metal core made of:

Stainless steel

Inconel

Carbon steel

Advantages:

Higher strength

Better blow-out resistance

Superior sealing under high pressure

Ideal for petrochemical and refinery environments.

3. Graphite Spiral Wound Gaskets

A combination of stainless steel and graphite filler.

Benefits:

High temperature resistance

Shock & vibration tolerance

Ideal for pipelines and flanges

4. Die-Formed Graphite Ring Gaskets

Precision-formed for high-pressure equipment.

Applications:

Pumps

Valves

High-pressure reactors

Steam systems

These rings provide excellent sealing in extreme conditions.

5. Graphite Laminate Gaskets

Graphite sheets bonded with metal layers.

Best for:

High bolt loads

Corrosive environments

High-pressure flanges

Key Features & Advantages of Graphite Gaskets

Graphite gaskets offer several advantages over rubber, fiber, PTFE, and metal gaskets.

1. Extreme Temperature Resistance

Graphite can withstand:

Up to 450°C in oxidizing conditions

Up to 650°C in steam

Up to 3000°C in non-oxidizing environments

Ideal for boilers, steam lines, and high-heat applications.

2. Excellent Chemical Resistance

Stable against:

Acids

Alkalis

Solvents

Hydrocarbons

Steam

Industrial chemicals

This makes graphite perfect for chemical and petrochemical industries.

3. High Compressibility & Recovery

Graphite conforms easily to flange imperfections, ensuring:

Tight sealing

Leak prevention

Long lifespan

4. Fire-Safe & Explosion Resistant

Reinforced graphite gaskets are widely used in fire-safe and explosion-prone zones.

5. Anti-Stick & Anti-Friction Properties

Easy removal even after long-term operation.

Applications of Graphite Gaskets Across Industries

Because of their durability and thermal properties, graphite gaskets are used in some of the harshest industrial environments.

1. Petrochemical & Refinery Industry

Used in:

High-pressure flange joints

Heat exchangers

Reactors

Pipe connections

2. Power Plants & Boilers

Graphite resists high heat and thermal cycling, ideal for:

Steam lines

Boiler connections

Turbine housings

3. Chemical Industry

Perfect for corrosive chemical environments.

4. Oil & Gas Pipelines

Graphite maintains sealing integrity under vibration and pressure.

5. Food & Pharmaceutical Machinery

Graphite does not contaminate or degrade with steam and cleaning chemicals.

How to Choose the Right Graphite Gasket

Before selecting a graphite gasket, consider the following:

Temperature range

- Pressure rating

- Exposure chemicals

- Flange surface condition

- Required thickness

- Reinforced vs pure graphite

- Application type (steam, chemicals, vacuum, pipelines)

For expert assistance in choosing the right gasket, CRI Gasket provides complete technical support.

Why Choose CRI Gasket for Graphite Gaskets?

CRI Gasket is a trusted name in industrial sealing solutions with:

High-quality pure and reinforced graphite gaskets

- Custom sizes and tailor-made solutions

- Precision die-formed graphite rings

- Compliance with industrial standards

- Durable and leak-proof gaskets

- Fast delivery and reliable service

Conclusion

Graphite gaskets are one of the strongest and most reliable sealing solutions for extreme industrial environments. Their resistance to high temperatures, pressure, and aggressive chemicals makes them ideal for boilers, reactors, heat exchangers, chemical plants, refineries, and power generation systems.

With CRI Gasket’s high-performance graphite gasket range, you get unmatched durability, precision manufacturing, and long-term operational reliability. Choose the right gasket today and ensure leak-proof, efficient industrial operations.