The Engineer’s Guide to Non-Asbestos Gaskets: Superior Sealing for Modern Industry

In the modern industrial landscape, safety and environmental compliance are paramount. The transition from asbestos to Non-Asbestos Compressed Fiber (CNAF) gaskets has allowed industries to achieve better gas tightness and chemical resistance while eliminating health risks.

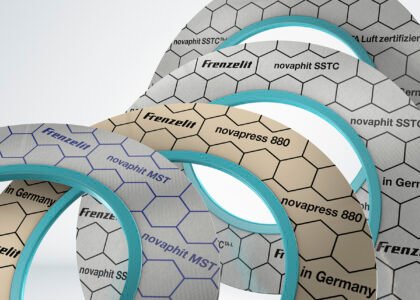

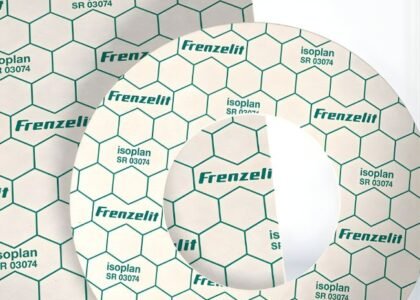

At CRI Gasket, we specialize in high-performance non-asbestos solutions, including the world-renowned Frenzelit Novapress and Novaphit ranges, tailored for precision and durability.

What is a Non-Asbestos Gasket?

A Non-Asbestos gasket is a sealing material made from a combination of synthetic fibers (like Aramid or Carbon), specialist fillers, and elastomeric binders (usually NBR – Nitrile Rubber). These components are “compressed” together under high pressure to create a dense, flexible sheet.

Which Non-Asbestos Gasket Grade Do You Need?

Selection depends on the “STAMP” criteria (Size, Temperature, Application, Media, and Pressure):

General Purpose: For water, low-pressure steam, and oils (e.g., Novapress Basic or 260).

High Gas Tightness: For refrigerants and fuels where leakage must be zero (e.g., Novapress 850).

Chemical & Steam: For aggressive media and saturated steam (e.g., Novapress Multi II or Universal).

Extreme Heat: If temperatures exceed 250°C, you should move to Graphite-based non-asbestos grades (e.g., Novaphit 400).

Types of Non-Asbestos Gaskets

Aramid Fiber Gaskets (CNAF): The most common type, offering excellent mechanical strength for general industrial use.

Carbon Fiber Gaskets: Designed for high-temperature and highly alkaline environments.

Graphite-Reinforced Gaskets: Pure expanded graphite with metal inserts for steam and high-pressure chemical lines.

PTFE Gaskets: Used specifically for highly corrosive acids and food-grade applications.

Key Features & Advantages

Environmental Safety: 100% asbestos-free, complying with global health and safety regulations.

High Stress Relaxation: Maintains bolt tension over time, reducing the need for maintenance.

Superior Gas Tightness: Modern non-asbestos materials are significantly denser than old asbestos sheets, meeting TA Luft clean air standards.

Non-Stick Coatings: Many grades come with factory-applied coatings (like PTFE or XP technology) to prevent the gasket from “baking” onto the flange

Applications Across Industries

Oil & Gas: Pipeline flanges, refineries, and storage tanks.

Chemical Processing: Handling solvents, acids, and volatile gaseous media.

Power Generation: Saturated steam lines, cooling systems, and heat exchangers.

Food & Pharma: FDA-compliant grades for processing and packaging equipment.

Automotive: Sealing for gearboxes, fuel pumps, and cooling circuits.

Why Choose CRI Gasket for Non-Asbestos Gaskets?

Choosing CRI Gasket means choosing technical precision:

Advanced Cutting Technology: We use CNC and water-jet cutting to ensure perfectly smooth edges and exact tolerances for standard or custom shapes.

Premium Material Selection: We stock the full Frenzelit range (Novapress and Novaphit), ensuring you get the highest quality German-engineered material.

100% Traceability: Our gaskets feature batch coding, which is essential for safety audits and quality control.

Expert Guidance: Our engineers assist you in calculating torque values to prevent over-compression or leaks.

Conclusion

The shift to Non-Asbestos Gaskets is not just a regulatory requirement—it is a performance upgrade. With better adaptability, higher density, and specialized chemical resistance, modern gaskets like those provided by CRI Gasket ensure your plant operates at peak efficiency with zero leakage.