The Engineer’s Guide to Frenzelit Novapress: Superior Sealing for Modern Industry

In high-stakes industrial environments, the difference between a seamless operation and a costly shutdown often lies in a single flange connection. While many industries rely on standard seals, Frenzelit Novapress has emerged as the premium standard for those who require precision, gas tightness, and mechanical robustness.

At CRI Gasket, we provide a comprehensive range of Novapress solutions—including the 260, 280, 850, Multi II, and Universal grades—each engineered to solve specific sealing challenges.

What is Frenzelit Novapress?

Novapress is a family of elastomer-bonded fiber gaskets. By combining high-quality aramid fibers with a specialized NBR (Nitrile Butadiene Rubber) binder, Frenzelit has created a material that offers:

Extreme Gas Tightness: Outperforming traditional fiber gaskets in preventing fugitive emissions.

High Stress Relaxation: Maintaining a secure seal even under constant mechanical load.

Non-Stick Performance: Reducing maintenance time during gasket replacement.

Which Novapress Grade Do You Need?

According to our product catalog at CRI Gasket, here is how the different grades serve your facility:

Novapress Universal: The “Gold Standard” for high-pressure and high-temperature applications. It is exceptionally resistant to chemicals and ideal for demanding liquid and gaseous media.

Novapress 850: Known for its extreme adaptability. It is the perfect bridge between a soft rubber gasket and a hard fiber gasket, making it ideal for uneven flanges or non-rigid housing seals.

Novapress Multi II: The steam specialist. Reinforced with graphite, it is designed to handle changing thermal loads and saturated steam environments where standard gaskets fail.

Novapress 260 & 280: The efficiency leaders. These provide an excellent price-performance ratio for standard industrial applications, including water, gas, and oil supply lines.

Types of Frenzelit Novapress

1. Novapress Universal (The High-Pressure Standard)

This serves as the high-performance fiber alternative to Pure Graphite or Graphite Laminate gaskets.

Features: Engineered with an optimized ratio of high-quality aramid fibers and an NBR binder.

Advantages: It possesses the highest mechanical strength in the fiber gasket category. Its superior density allows it to outperform graphite in terms of gas tightness.

Best For: High-pressure liquid and gaseous media, chemical processing plants, and general mechanical engineering.

2. Novapress 850 (The Adaptable Hybrid)

The ideal solution for “non-rigid” systems or applications where flanges are slightly uneven or distorted.

Features: Offers 3x higher adaptability compared to standard compressed fiber gaskets.

Advantages: It creates a reliable seal even under low bolt loads (torque), a characteristic usually found only in soft graphite or rubber gaskets.

Best For: Pump housings, gearboxes, and lightweight or fragile flanges.

3. Novapress Multi II (Graphite-Reinforced Fiber)

The fiber-based equivalent to Reinforced Graphite Gaskets, designed for thermal endurance.

Features: A sophisticated blend of aramid fibers integrated with graphite components.

Advantages: Provides significantly higher thermal stability than standard fiber gaskets. It manages thermal cycling (frequent temperature changes) with the same efficiency as pure graphite.

Best For: Saturated steam applications, boilers, and heat exchangers.

4. Novapress Multi II EG (Wire Mesh Reinforced)

Designed for “Extreme Duty” applications, similar to Tanged or Metal-Reinforced Graphite.

Features: Reinforced with an internal Stainless Steel wire mesh (expanded metal layer).

Advantages: Provides exceptional blow-out resistance, ensuring the gasket does not rupture or displace even under extreme pressure surges.

Best For: High-pressure steam lines and hazardous chemical zones where safety is critical.

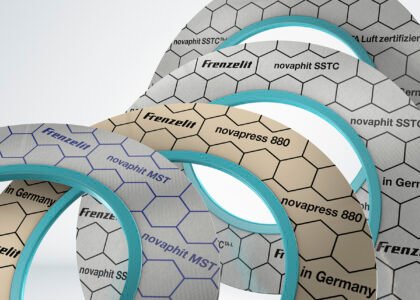

5. Novapress 880 (High-Tech Compliance)

The premium choice for modern industries targeting zero-leakage and environmental safety.

Features: Achieves a perfect balance between soft adaptability and high mechanical surface pressure resistance.

Advantages: Fully meets TA Luft (Clean Air) regulations, ensuring virtually zero fugitive emissions.

Best For: Environmentally sensitive sectors and refineries requiring the highest sealing efficiency.

Key Features & Advantages of Frenzelit Novapress

1. Key Technical Features

Aramid Fiber & NBR Matrix: A balanced combination of high-quality aramid fibers and special functional fillers bonded with Nitrile Butadiene Rubber (NBR). This creates a material that is both mechanically strong and chemically resistant.

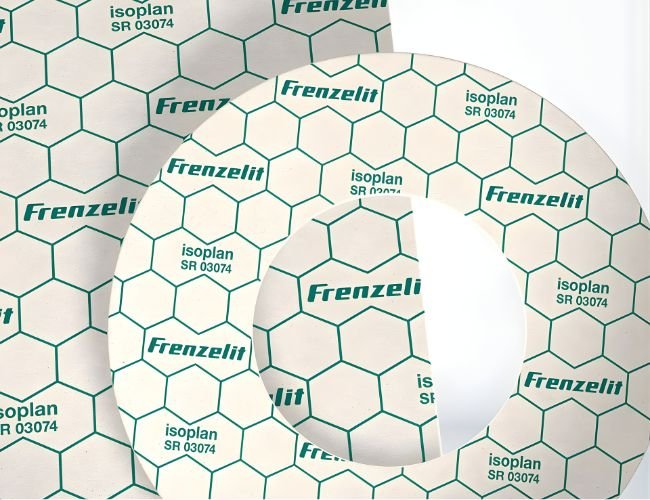

Gasket Code Technology: Every sheet features a unique, permanent “fingerprint.” This allows for Industry 4.0 traceability, meaning maintenance teams can identify the material and production batch even years after installation.

Superior Gas Tightness: Novapress gaskets are engineered to be significantly denser than conventional fiber gaskets. For example, Novapress 850 is 10,000 to 100,000 times denser than standard products, virtually eliminating fugitive emissions.

High Adaptability: Types like Novapress 880 and 850 offer up to 3x higher adaptability to flange unevenness compared to classic fiber gaskets, allowing for a tight seal even at low surface pressures.

2. Major Advantages

Extended Service Life: Excellent stress relaxation (low “creep”) ensures that the gasket maintains its sealing force over time, even under fluctuating temperatures.

Easy Maintenance (Non-Stick): Most Novapress gaskets come standard with a specialized non-stick coating (often PTFE-based). This prevents the gasket from “baking” onto the flange, making removal fast and protecting the flange surface from damage.

Broad Chemical Resistance: Highly resistant to oils, fuels, lubricants, and various gases. Specialized types like Novapress Multi II are optimized for saturated steam.

Hydrogen Ready (H2-Approved): Frenzelit has tested and approved Novapress materials for use in the emerging hydrogen sector, ensuring long-term stability against the smallest molecules.

3. Safety & Environmental Compliance

TA Luft (Clean Air) Compliance: Meets the strictest leakage requirements, making it ideal for facilities aiming for zero-emission targets.

Global Certifications:

Drinking Water: DVGW, W270, and WRAS approved.

Food Safety: Certified according to EC 1935/2004 and FDA standards.

Gas Safety: HTB (High Temperature Resistance) and VP-401 approved for gas supply.

Applications of Frenzelit Novapress Across Industries

1. Energy & Power Generation

Novapress is the “safe bet” for energy infrastructure where pressure and temperature fluctuate constantly.

Hydrogen Energy: Specialized “H2-approved” Novapress grades are used in hydrogen production and transport, providing a leak-proof seal for the smallest known molecules.

Renewable Energy: Used in solar thermal plants and wind turbine gearboxes (specifically Novapress 850) due to its vibration resistance and adaptability.

Steam Systems: Novapress Multi II is widely used in power plant boiler systems and saturated steam lines (up to 250°C).

2. Chemical & Petrochemical Industry

In an industry where a single leak can be an environmental disaster, Novapress provides TA Luft (Clean Air Act) compliance.

Pipeline Flanges: Novapress Universal is the standard for transporting oils, fuels, solvents, and various gaseous media.

Refineries: Used in heat exchangers and reactors where high stress relaxation (resistance to “creep”) is required to maintain a seal over months of operation.

3. Food & Pharmaceutical Industry

Safety and hygiene are paramount here. Novapress grades are manufactured to meet global compliance standards.

Processing Equipment: Used in filling machines and processing vats where gaskets must be FDA and EC 1935/2004 compliant.

Clean Environments: Its non-stick coating ensures that during washdowns and maintenance, no gasket residue is left behind to contaminate the production line.

4. Gas & Water Utilities

Novapress is a primary choice for municipal infrastructure due to its long-term reliability.

Drinking Water: Approved under DVGW, W270, and WRAS, ensuring no harmful chemicals leach into the water supply.

Gas Transfer Stations: Used in natural gas pipelines and gas meters because of its exceptional gas tightness (achieving 0 ppm leakage in many case studies).

5. Automotive & Mechanical Engineering

For high-volume manufacturing, Novapress offers mechanical stability that elastomer (rubber) gaskets cannot match.

Gearboxes & Transmissions: Novapress 850 is used for housing covers because it adapts to slightly uneven surfaces while resisting hot oils and fuels.

Pump & Compressor Housings: Ideal for components with large screw spacing where the gasket must compensate for uneven pressure distribution.

6. Shipbuilding & Marine Engineering

Novapress is “Sea-water resistant” and approved by maritime classification societies.

Engine Room Systems: Used in cooling systems, fuel lines, and exhaust management where high vibration and salt-air corrosion are common.

How to Choose the Right Frenzelit Novapress

Choosing the right Frenzelit Novapress gasket is a balance of three critical factors: the Media (what are you sealing?), the System Conditions (pressure and temperature), and the Flange Quality (is the hardware perfect or uneven?).

Here is a step-by-step guide to selecting the correct grade for your application.

Step 1: Check Your Media (Chemical Compatibility)

Different Novapress grades use different fiber/filler blends to handle specific fluids.

For Saturated Steam or Hot Oil: Choose Novapress Multi II. Its graphite content is specifically designed to handle the thermal stress of steam.1

For Aggressive Chemicals / Oxygen: Choose Novapress Universal. It has the highest chemical resistance in the aramid-fiber family and is BAM-approved for oxygen.

For Natural Gas or Drinking Water: Choose Novapress 260 or Basic. These are optimized for utility-grade safety and hold DVGW and W270 certifications.

For Refrigerants / Fuels: Choose Novapress 850.2 It is 10,000x denser than standard fiber gaskets, preventing the leakage of thin, “searching” media like refrigerants.

Step 2: Evaluate Flange Condition & Bolt Load

One of the most common reasons for gasket failure is choosing a “hard” gasket for a “soft” or uneven flange.

Uneven or Lightweight Flanges: Use Novapress 850. It has 3x higher adaptability than standard gaskets. If your bolts can’t provide high torque (low-rigidity structures), the 850 grade acts like an elastomer to fill gaps.

Precision/Rigid Flanges: Use Novapress Universal. This is a mechanically tough, high-density gasket that requires standard industrial bolt loads to seat properly.

Strict Emission Requirements (TA Luft): Use Novapress 880. It is engineered to meet the highest “Clean Air” standards even with manual installation.

Step 3: Consider Temperature & Pressure (The PxT Factor)

While Novapress is generally rated for temperatures between -100°C and +250°C, performance drops as pressure increases.

| Grade | Max Temp (Continuous) | Max Pressure | Best Technical Advantage |

| Universal | 250°C | 100 bar | Highest mechanical robustness. |

| 850 | 200°C | 80 bar | Hybrid fiber-elastomer behavior. |

| Multi II | 250°C | 100 bar | Excellent for changing thermal loads. |

| Basic / 260 | 150°C – 200°C | 40 – 60 bar | Best price-performance for plumbing. |

Step 4: Look for “Future-Proof” Features

If your industry is moving toward Hydrogen or Digital Maintenance, look for these specific logos on the Frenzelit data sheets:

H2-Approved: Verified for hydrogen tightness.

Gasket Code: Look for the printed code on the sheet to ensure you can trace the batch number during future audits.

Why Choose Frenzelit Novapress Gaskets ?

1. High-Performance Aramid Fiber Technology

Compared to traditional graphite gaskets, Novapress grades (such as Universal and 850) provide superior mechanical strength and gas tightness. These gaskets are considered the industry standard for sealing high-pressure liquids and gaseous media.

2. Custom Sizes & Tailor-Made Solutions

We process Frenzelit Novapress sheets using advanced CNC and water-jet cutting technology. This allows us to deliver:

Standard ANSI/ASME flange gaskets.

Custom-engineered gear-box housings and pump seals.

Complex, bespoke shapes designed specifically for your proprietary industrial equipment.

3. Gasket Code Technology for 100% Traceability

The standout feature of the Novapress range is its Gasket Code. Each gasket is printed with a unique code, allowing you to trace the material origin and production batch instantly. This feature is essential for audit-heavy sectors such as the Pharmaceutical and Oil & Gas industries.

4. Compliance with Strict Global Standards

Our Novapress gaskets come with world-class international certifications, ensuring safety and quality:

TA Luft: Guaranteed zero-leakage compliance (Clean Air Act).

FDA & EC 1935/2004: Certified for food-grade safety.

DVGW & W270: Approved for use in drinking water and gas supply infrastructure.

5. Durable, Leak-Proof & Adaptable

While graphite can be brittle and fragile, Novapress is engineered for durability and flexibility. Specific grades like Novapress 850 offer 3x higher adaptability, ensuring a leak-proof seal even on uneven or distorted flanges.

6. Fast Delivery & Technical Expertise

At CRI Gasket, we maintain a massive inventory of Novapress stock to ensure you never have to wait during Emergency Maintenance or unplanned shutdowns. Additionally, our engineering team provides expert technical support to help you select the precise grade (Universal, Multi II, or 850) for your application.

Conclusion

Final Verdict: Why It Matters

Whether you are managing a high-pressure chemical plant or maintaining a municipal water system, Novapress provides three things that are non-negotiable in modern industry:

Safety & Compliance: With TA Luft and FDA/DVGW approvals, you are guaranteed a seal that meets the world’s strictest environmental and health standards.

Operational Efficiency: The non-stick coating and high stress relaxation mean fewer leaks and faster gasket replacements during maintenance shutdowns.

Digital Traceability: The integrated Gasket Code Technology ensures that your facility is “Industry 4.0 ready,” allowing for full accountability and audit-proof documentation.