The Complete Guide to Flange Gaskets: Types, Uses & Why They Matter in Industrial Sealing

Industrial pipelines, chemical processing units, oil & gas connections, and mechanical assemblies rely heavily on leak-proof sealing. Among all sealing accessories, flange gaskets are the most widely used and the most critical in ensuring safe, reliable, and efficient operations.

If your industry deals with fluids, gases, steam, chemicals, or high-pressure media, choosing the right flange gasket is non-negotiable. As a trusted supplier of premium industrial gaskets, CRI Gasket offers high-quality solutions tailored for diverse applications.

In this detailed guide, we break down everything you need to know about flange gaskets from their types and materials to installation best practices and industry applications.

What Is a Flange Gasket?

A flange gasket is a mechanical sealing component designed to fill the microscopic gaps between two flange faces. When compressed between flanges, it creates a tight, reliable seal that prevents leakage of liquids or gases.

Why Flange Gaskets Are Essential

Prevent hazardous leaks

Maintain optimal pressure levels

Enhance equipment safety

Reduce downtime and maintenance

Improve system efficiency

Provide resistance against chemicals, heat, and corrosion

Without a proper gasket, even a small leak can result in catastrophic failures, especially in industries handling high-pressure or chemically aggressive media.

How Flange Gaskets Work

When a flange gasket is compressed using bolted pressure, it molds itself to the flange’s surface irregularities. This creates a uniform sealing barrier that can withstand:

High pressure

High temperature

Vibrations

Mechanical stress

Different gasket materials behave differently under stress, which is why material selection is a key factor in achieving a long-lasting and leak-proof seal.

Types of Flange Gaskets

Flange gaskets come in several types based on material, design, and application. Below are the most commonly used types across industries.

1. Spiral Wound Gaskets (SWG)

One of the most preferred sealing solutions for high-pressure & high-temperature pipelines.

Features

Combines metal and filler material

Excellent recovery under fluctuating conditions

High blowout resistance

Used in chemical plants, oil refineries, power plants

2. Ring Type Joint (RTJ) Gaskets

Designed specifically for high-pressure applications such as oil & gas drilling, refinery pipelines, petrochemical units, and offshore equipment.

Advantages

High sealing efficiency

Resistant to extreme temperature and pressure

Made from solid metal such as carbon steel, stainless steel, Inconel, etc.

3. Non-Metallic Flange Gaskets

Materials include:

Rubber (NBR, EPDM, Neoprene, Silicone)

PTFE (Teflon gaskets)

Fiber

Graphite

Ideal for:

Low-to-medium pressure

Water pipelines

Chemical pipelines

HVAC systems

Food & beverage equipment

They are flexible, cost-effective, and corrosion-resistant.

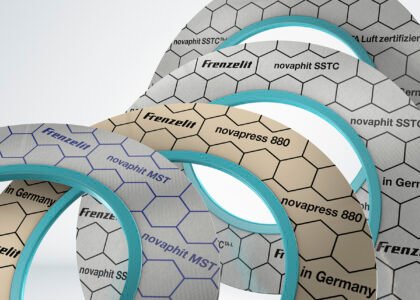

4. Metallic Gaskets

Manufactured from high-strength metals, these are suitable for extreme conditions.

Common types:

Corrugated metal gaskets

Kammprofile gaskets

Solid metal gaskets

They offer excellent durability and are used in:

Boilers

Heat exchangers

High-pressure vessels

5. Compressed Fiber Gaskets (CNAF)

Constructed by compressing synthetic fibers with elastomer binders.

Benefits:

Cost-effective

Easy to install

Suitable for steam, oil, mild chemicals

Flange Gasket Materials: Choosing the Right One

The performance of a gasket depends largely on its material. Below are commonly used gasket materials and their applications.

Rubber (NBR, EPDM, Neoprene)

Best for water, mild chemicals, oils.

PTFE (Teflon)

Chemical-resistant, ideal for aggressive fluids, acids, solvents.

Graphite

Perfect for high-temperature applications, supports thermal cycling.

Metal (SS 304, SS 316, Monel, Inconel)

Used in extreme temperature and pressure environments.

Fiber (Aramid, Cellulose, CNAF)

General-purpose industrial sealing applications.

Applications of Flange Gaskets Across Industries

Flange gaskets are used in a wide range of industries, including:

Oil & Gas

Petrochemical and Chemical

Power Generation

Water Treatment

Food & Beverage

Pharmaceuticals

Marine and Offshore

Heavy Machinery

HVAC Systems

Pulp and Paper

Whether you operate pipelines, heat exchangers, boilers, storage tanks, or reactors, proper gasket sealing is essential.

Advantages of Using High-Quality Flange Gaskets

Using superior-grade flange gaskets such as those offered by CRI Gasket ensures:

Zero Leakage

Maintains system integrity under all conditions.

Higher Safety

Prevents hazardous leaks and reduces chances of accidents.

Lower Maintenance

Durable materials extend the operational life of your equipment.

Cost Efficiency

Reduced downtimes and lower replacement frequency.

Compatibility

Available for all flange standards:

ANSI

DIN

BS

JIS

ISO

Why Choose CRI Gasket for Flange Gaskets?

As a trusted industrial gasket manufacturer, CRI Gasket provides:

Premium-grade materials

Precision-engineered gasket designs

High-temperature and high-pressure resistant seals

All flange sizes and standards

Customized gasket solutions

Fast delivery & excellent customer support

Conclusion

Flange gaskets are essential components in ensuring leak-proof and safe industrial operations. From selecting the correct type to installing them properly, every step plays a key role. With premium-quality solutions from CRI Gasket, industries can achieve long-lasting sealing performance, minimal downtime, and maximum safety.