Rubber Gasket – Types, Materials, Industrial Applications & Benefits

Rubber gaskets are one of the most commonly used sealing components in mechanical, industrial, pipeline, and fluid-transfer systems. Their flexibility, durability, and chemical resistance make them ideal for sealing joints, preventing leaks, and ensuring safe operation in both low and high-pressure environments.

Industries rely heavily on rubber gaskets for sealing air, gas, water, oil, chemicals, and other fluids. If you are looking for high-performance and accurately engineered rubber gaskets.

In this comprehensive guide, we explain everything you need to know about rubber gaskets:

- Types

- Materials

- Applications

- Advantages

- How to choose the right gasket

What is a Rubber Gasket?

A rubber gasket is a flexible sealing component designed to create an airtight or watertight barrier between two mating surfaces. These gaskets absorb vibrations, compensate for surface irregularities, and prevent leakage of liquids or gases.

Rubber gaskets are widely used because they are:

Highly flexible

Durable

Resistant to chemicals

Easy to install

Cost-effective

Different types of rubber materials are used depending on the application’s temperature, pressure, and chemical exposure.

Types of Rubber Gaskets

Rubber gaskets come in various types based on material composition and intended usage. Here are the most commonly used ones:

1. Nitrile Rubber Gasket (NBR)

Known for its excellent oil and fuel resistance, NBR rubber gaskets are widely used in automotive, oil & gas, and hydraulic equipment.

Best For:

Oils

Fuels

Grease

Petroleum-based fluids

2. EPDM Rubber Gasket

EPDM is an all-weather rubber material with outstanding resistance to UV, ozone, and steam.

Best For:

Water systems

Outdoor applications

Steam sealing

HVAC applications

3. Neoprene Rubber Gasket

Neoprene is a versatile rubber used for general-purpose sealing.

Best For:

Mild chemicals

Refrigerants

Weather sealing

Medium temperature applications

4. Silicone Rubber Gasket

Silicone gaskets handle extreme temperature variations, making them suitable for sensitive equipment.

Best For:

Food & pharmaceutical systems

Medical devices

High-temperature sealing

Cleanroom equipment

5. Viton Rubber Gasket (FKM)

Viton is the most robust rubber material for chemical and temperature resistance.

Best For:

Aggressive chemicals

High-temperature applications

Hazardous industrial environments

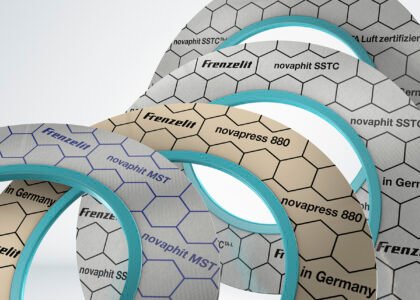

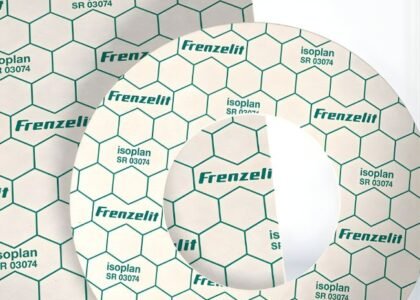

Common Shapes of Rubber Gaskets

Rubber gaskets are available in multiple shapes depending on where they are used.

Most common for flanges & pipeline systems.

Circular rubber sealing rings used in hydraulic & pneumatic systems.

3. Custom-Cut Rubber Gaskets

Made in any shape (rectangular, square, irregular) based on equipment needs.

Materials Used in Rubber Gaskets

Rubber gaskets are made from natural or synthetic elastomers. The material determines the gasket’s:

Temperature resistance

Durability

Chemical compatibility

Compression strength

Common Rubber Materials:

NBR (Nitrile)

EPDM

Neoprene

Silicone

Viton (FKM)

SBR (Styrene-Butadiene Rubber)

Natural Rubber

Each material serves unique industrial applications.

Applications of Rubber Gaskets

1. Plumbing & Water Supply Systems

EPDM rubber gaskets provide leak-proof sealing for:

Pipes

Valves

Flanges

Water meters

Pumps

2. Oil & Gas Industry

Nitrile and Viton gaskets are widely used for:

- Oil refineries

Fuel tanks

Compressors

Petroleum pipelines

3. Automotive & Transportation

Used for sealing:

Engine components

Fuel systems

Transmission lines

Air conditioning units

4. Chemical Industry

PTFE-backed rubber gaskets and Viton gaskets resist aggressive chemicals.

5. Food & Pharmaceutical Industry

Silicone rubber gaskets ensure hygiene and FDA compliance.

6. HVAC & Air Handling Units

Rubber gaskets help in sealing ducts, preventing air leakage, and maintaining pressure.

7. Electrical Enclosures & Electronics

Rubber gaskets protect against dust, moisture, and vibration.

Advantages of Rubber Gaskets

Rubber gaskets offer many advantages that make them suitable for industrial applications.

1. Excellent Flexibility

Rubber easily adapts to irregular surfaces and ensures uniform sealing.

2. Vibration Absorption

Ideal for machinery and automotive systems.

3. Chemical & Weather Resistance

EPDM and Viton rubber withstand harsh chemicals and environmental exposure.

4. Cost-Effective

Affordable and long-lasting, making them suitable for large-scale industrial use.

5. Easy to Install

Rubber gaskets can be installed quickly without specialized tools.

6. High Durability & Load Resistance

Withstands compression, temperature shifts, and mechanical stress.

How to Choose the Right Rubber Gasket

Follow these factors to select the perfect gasket for your application:

1. Temperature Requirement

Silicone & Viton: high temp

EPDM: moderate

Nitrile: low-to-medium

2. Pressure Conditions

Higher pressure applications may require reinforced rubber gaskets.

3. Chemical Compatibility

Match the rubber material to the chemical medium.

4. Size & Thickness

Ensure accurate measurements to avoid leakage.

5. Application Environment

Outdoor, indoor, underwater, chemical, high heat choose accordingly.

Why Choose CRI Gasket for Rubber Gaskets?

CRI Gasket is a trusted name in precision sealing solutions, offering high-quality rubber gaskets for all industrial applications.

What Makes Us the Best Manufacturer?

High-grade rubber materials

Precise engineering & consistent quality

Custom gasket manufacturing

Excellent sealing performance

High durability & reliability

Nationwide delivery

Competitive pricing

Conclusion

Rubber gaskets are indispensable sealing components used across industrial, automotive, and mechanical systems. Their flexibility, strength, and chemical resistance make them ideal for both light-duty and heavy-duty applications.

Whether you need Nitrile, EPDM, Silicone, Neoprene, or Viton rubber gaskets, CRI Gasket offers premium-quality solutions tailored to your needs.