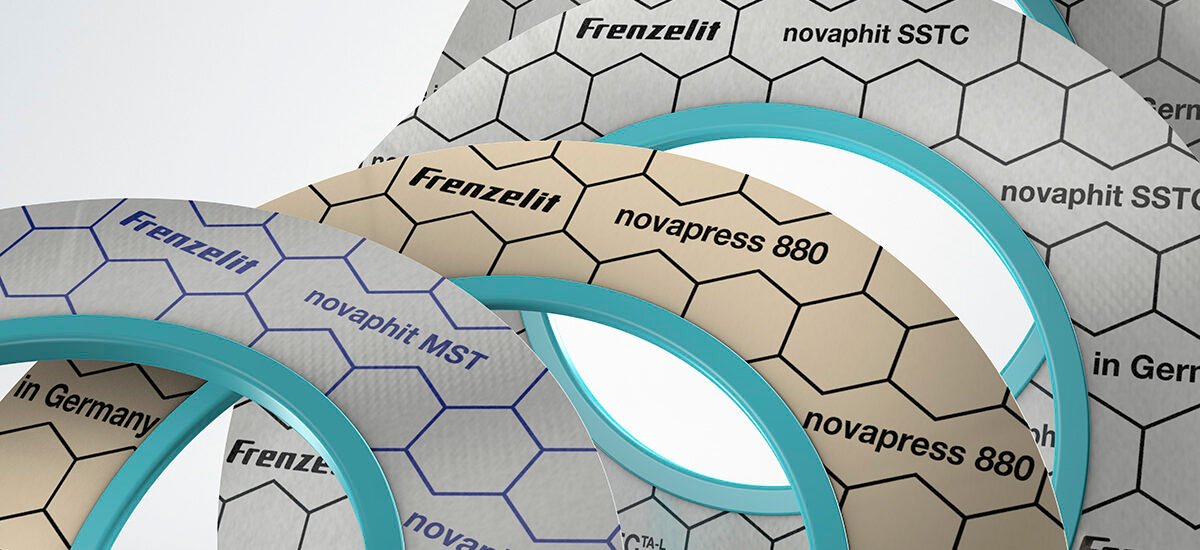

The Engineer’s Guide to Frenzelit Novaphit 400: Superior Sealing for Modern Industry

In high-stakes industrial environments, the difference between a seamless operation and a costly shutdown often lies in a single flange connection. While many industries rely on standard seals, Frenzelit Novapress has emerged as the premium standard for those who require precision, extreme temperature resistance, and mechanical robustness.

At CRI Gasket, we provide professional-grade Novaphit 400 solutions, engineered to solve the most demanding sealing challenges in high-heat and high-pressure systems.

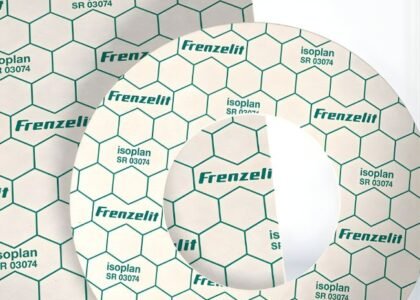

What is Frenzelit Novaphit 400?

Novaphit 400 is a high-performance reinforced graphite gasket. It is composed of expanded graphite (99% purity) reinforced with a flat stainless steel insert (AISI 316L).

Unlike standard fiber gaskets, the Novaphit 400 series offers:

Extreme Heat Resistance: Reliable performance up to 500°C.

Mechanical Strength: The 316L stainless steel core prevents “blow-outs” and makes the gasket easier to handle.

Chemical Versatility: Resistant to almost all organic and inorganic acids, alkalis, and solvents.

Which Frenzelit Novaphit 400 Grade Do You Need?

According to our product catalog at CRI Gasket, we offer Novaphit 400 in variations to suit your maintenance strategy:

Novaphit 400 (Standard): The versatile “all-rounder” for intricate gasket shapes and high-temperature liquid/gas media.

Novaphit 400 with XP Technology: This version features an inorganic anti-stick coating. It is the best choice if you want to prevent the gasket from “baking” onto the flange surface, reducing downtime during maintenance.

Types of Frenzelit Novaphit

1. Novaphit® 400 (Standard)

This is the base version of the 400 series. It consists of high-purity expanded graphite (at least 98% pure) reinforced with a flat stainless steel insert (AISI 316L).

Key Advantage: Because the metal insert is flat (not spiked/tanged), it can be cut into very intricate shapes without the metal layers fraying or burring.

Best For: Intricate gasket geometries, pump housings, and delicate valve covers.

2. Novaphit® 400 with XP Technology

This is a premium version where the graphite surface is enhanced with Frenzelit’s proprietary XP Technology (an inorganic anti-stick coating).

Key Advantage: It eliminates the need for technicians to scrape off “baked-on” graphite during maintenance. The gasket releases cleanly from the flange.

Best For: Equipment that requires frequent maintenance or fast turnaround during shutdowns.

3. Novaphit® 400 (Low-Chloride Grade)

For specialized applications in the nuclear or power industry, a high-purity version with extremely low chloride content is used.

Key Advantage: It prevents stress corrosion cracking in sensitive stainless steel piping systems.

Best For: Nuclear power facilities and ultra-high-pressure steam turbines.

Key Features & Advantages of Frenzelit Novaphit 400

1. High Stress Relaxation

Graphite does not “flow” or creep like fiber gaskets do. Once the bolts are torqued, Novaphit 400 maintains its surface pressure even under constant mechanical load, ensuring a long-term, leak-proof seal.

2. Superior Gas Tightness

Novaphit 400 is engineered to prevent fugitive emissions. Its high-density graphite structure meets the strictest environmental standards, making it a favorite for modern refineries.

3. Easy Handling and Processing

The flat metal insert allows for clean, burr-free cutting. Whether you use a CNC machine or a water-jet, the material remains stable without delaminating, protecting both the technician and the flange.

Applications Across Industries

Energy & Power Generation: Ideal for high-pressure steam pipes, boiler systems, and valve connections where temperatures exceed 300°C.

Chemical & Petrochemical: Used in heat transfer oil systems and reactors involving aggressive chemical media.

Oil & Gas: Reliable sealing in refineries for both upstream and downstream processing equipment.

Machine & OEM Engineering: Perfect for complex shapes in pump housings, gearboxes, and compressors.

How to Choose the Right Novaphit 400

Choosing the right gasket is a balance of Media, Temperature, and Pressure:

Check the Temperature: If your system runs between 250°C and 500°C, Novaphit 400 is the correct choice over fiber-based Novapress.

Evaluate Flange Quality: Novaphit 400 is highly adaptable; use 1.5mm to 2.0mm thickness for standard flanges, or 3.0mm if the flange surface has scratches or pits.

Future-Proof with XP: If the gasket is in a hard-to-reach area, always choose the XP anti-stick version to ensure easy removal in the future.

Why Choose CRI Gasket for Frenzelit Novaphit 400?

Precision Cutting: We utilize advanced CNC technology to ensure every Novaphit 400 gasket fits your hardware perfectly, with no exposed metal burrs.

Genuine Quality: We provide 100% authentic Frenzelit materials with full batch traceability.

Fast Turnaround: We maintain a deep inventory of Novaphit 400 sheets to fulfill emergency maintenance orders immediately.

Technical Expertise: Our team helps you calculate the correct bolt torque and surface pressure to ensure a perfect seal the first time.

Conclusion

Frenzelit Novaphit 400 is the ultimate balance between the thermal power of pure graphite and the mechanical strength of stainless steel. For industries that cannot afford a leak, this material provides a safety margin that standard seals simply cannot reach.