| Material | Premium Grade Silicon Rubber |

|---|---|

| Shore Hardness | 30° to 70° Shore A (Customizable) |

| Operating Temp. | -60°C to +250°C |

| Suction Force | High-Traction Vacuum Stability |

| Chemical Resistance | Excellent (Ozone, UV, and Oxidation) |

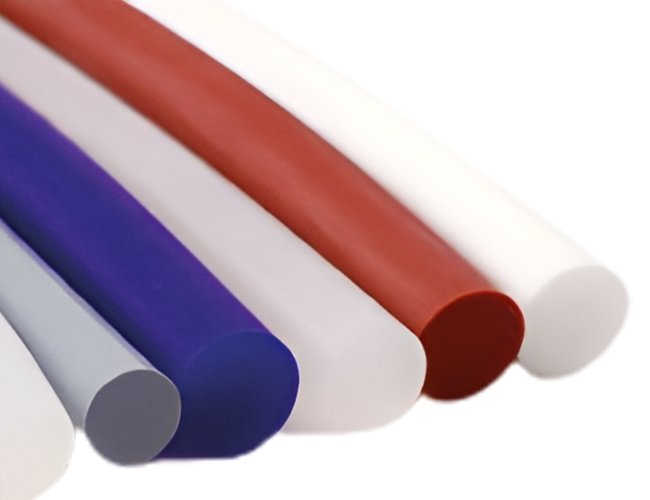

| Available Colors | Transparent, Blue, Red, Orange, Black |

CRI Gasket is a leading Silicon Rubber manufacturer and Industrial Flange Gasket manufacturer, providing high-precision sealing for extreme temperatures. Our Silicon Rubber products, including Silicone O-Rings and Silicon rubber sheets, are engineered to operate between -60°C to +250°C. As a trusted Industrial Flange Gasket supplier and Industrial Flange Gasket exporter, we ensure our Silicone components are FDA-compliant for pharma and food industries.

We specialize in industrial round gasket manufacturer services, offering Silicon Rubber solutions that serve as a durable Round gasket. Whether you need a Round gasket supplier, industrial round gasket supplier, or industrial round gasket exporter, our Silicone Rubber range provides excellent UV and ozone resistance. For high-speed automation, we integrate Silicone into our Vacuum Suction Cup and Bellows Suction Cups technology.

| Material | Premium Grade Silicon Rubber (VMQ) |

|---|---|

| Hardness Range | 20 - 80 Shore A (Customizable) |

| Internal Diameter (ID) | Available in All Standard & Custom Sizes |

| Operating Temp. | -60°C to +250°C (High Thermal Stability) |

| Color | Red, Transparent, Orange, or Custom |

| Chemical Resistance | Excellent UV, Ozone, and Weathering resistance |

| Main Market | Mumbai, Maharashtra, India |

CRI Gasket is a specialized Silicon Rubber manufacturer and Aflas O Ring Supplier, producing high-performance Silicone O-Ring (VMQ) seals for mission-critical applications. These Round gasket components are renowned for their high thermal stability, maintaining flexibility from -60°C to +250°C. As a leading Industrial Flange Gasket manufacturer and Industrial Flange Gasket exporter, we provide FDA-compliant Silicone O-Ring solutions for the medical, pharma, and food industries.

Our expertise as an industrial round gasket manufacturer and industrial round gasket supplier ensures that every Silicone O-Ring provides a reliable vacuum seal. Whether you need a Round gasket supplier or an industrial round gasket exporter, we offer custom durometers (20 to 80 Shore A) for Vacuum Suction Cup and Bellows Suction Cups. We also stock specialized Viton / FKM Gasket and Aflas Gasket Supplier grades for combined chemical and heat resistance.

| Material | Premium Grade Silicon Rubber |

|---|---|

| Shore Hardness | 30° to 70° Shore A (Customizable) |

| Operating Temp. | -60°C to +250°C |

| Suction Force | High-Traction Vacuum Stability |

| Chemical Resistance | Excellent (Ozone, UV, and Oxidation) |

| Available Colors | Transparent, Blue, Red, Orange, Black |

CRI Gasket is a premier Silicon Rubber manufacturer and Industrial Flange Gasket manufacturer, specialized in high-grade Silicon rubber sheets. Our Silicone Rubber sheets are designed for extreme environments, offering unmatched thermal insulation and flexibility from -60°C to +250°C. As a leading Industrial Flange Gasket exporter and Industrial Flange Gasket supplier, we provide Silicone sheeting that meets FDA-compliant standards for food, medical, and pharmaceutical sectors.

As a trusted industrial round gasket manufacturer and Round gasket supplier, we offer Silicon rubber sheets in various thicknesses (0.5mm to 20mm) and shore hardness (30 to 80 Shore A). Whether you need an industrial round gasket supplier or industrial round gasket exporter, our sheets are ideal for custom Round gasket cutting and Vacuum Suction Cup fabrication. Our Silicone material ensures a reliable vacuum seal and resistance to UV, ozone, and weathering.