| Inner Diameter (ID) | 300 mm |

|---|---|

| Material | Rubber |

| Usage/Application | Automobile |

| Shape | Round |

| Color | Black |

| Packaging Type | Packet |

| Thickness | 10 mm |

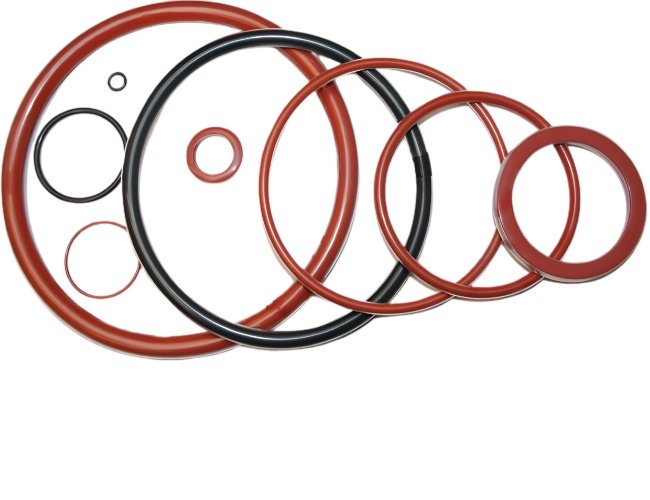

Kalrez and Aflas O-rings are high-performance sealing components designed for the most aggressive industrial environments. While both offer exceptional chemical resistance, Kalrez (FFKM) provides wider chemical compatibility and a Superior Thermal Range up to 327°C. In contrast, Aflas (FEPM) excels in steam resistance, base resistance, and sour gas (H2S) environments, making it a cost-effective alternative to premium perfluoroelastomers.

As a leading Industrial Flange Gasket manufacturer and Aflas O Ring Supplier, CRI Gasket ensures both materials outperform standard Viton / FKM Gasket and Silicon Rubber in extreme applications. If you are comparing Kalrez vs Aflas price or looking for the best Aflas gasket price list in India, our engineering team provides tailored dimensions and thicknesses for oil and gas, pharmaceutical, and chemical processing sectors.

Whether you need a Round gasket, industrial round gasket, or FFKM O-rings, we are a trusted Industrial Flange Gasket exporter and Industrial round gasket manufacturer. Our 2026 product range includes Frenzelit Novaflon Manufacturer grades and Garlock Gasket equivalents to guarantee Universal Chemical Resistance. Request our Kalrez and Aflas specification pdf for a detailed performance comparison.

| Inner Diameter (ID) | 25 mm |

|---|---|

| Material | FFKM Viton |

| Usage/Application | Industrial |

| Shape | Round |

| Packaging Type | Box |

| Thickness | 3.5 mm |

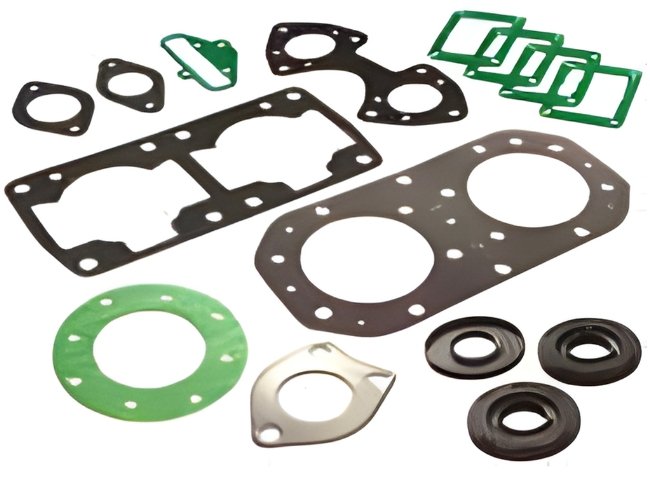

FFKM currently offers the highest operating temperature range and the most comprehensive chemical compatibility in the industry. Due to the ultra-strong bond between the carbon-atom and fluorine-atom, FFKM gaskets and O-rings provide the lowest off-gassing and extractable levels. As a leading Industrial Flange Gasket manufacturer and Industrial Flange Gasket exporter, CRI Gasket provides FFKM solutions that outperform Viton / FKM Gasket and Silicon Rubber in extreme vacuum and high-heat conditions.

If you are searching for FFKM O-ring price, FFKM price per kg, or the FFKM gasket price in India, we offer the most competitive rates for high-purity sealing. Our FFKM range is a superior alternative to DuPont Kalrez and Aflas Gasket Manufacturer grades, ensuring Universal Chemical Resistance for semiconductor and pharmaceutical sectors. Whether you need a Round gasket or an industrial round gasket, our FFKM materials guarantee zero-leakage durability.

As an expert Industrial Flange Gasket supplier and Industrial round gasket manufacturer, we provide technical support via our FFKM specification pdf. For industries requiring Garlock Gasket or PHE Gasket standards, CRI Gasket delivers custom FFKM seals alongside our Spiral Wound Gasket and PTFE/ Teflon Gasket inventory to ensure maximum safety in aggressive environments.

| Inner Diameter (ID) | 300 mm |

|---|---|

| Material | Rubber |

| Usage/Application | Industrial |

| Shape | Round |

| Packaging Type | Packet |

| Thickness | 10 mm |

DuPont Kalrez O-rings are premium FFKM (perfluoroelastomer) parts designed to withstand extreme temperatures up to 327°C and exposure to over 1,800 aggressive chemicals. As a leading Industrial Flange Gasket exporter and Aflas O Ring Supplier, CRI Gasket provides Kalrez solutions for critical sealing in the pharmaceutical, oil and gas, and aerospace industries.

If you are searching for the Kalrez O-ring price in India or a Kalrez O-ring price list, we offer genuine high-performance seals that reduce downtime. These FFKM gaskets outperform standard Viton / FKM Gasket and Silicon Rubber in the most corrosive environments. Whether you need Kalrez 6375, Kalrez 7075, or Aflas Gasket Manufacturer grades, we ensure Universal Chemical Resistance.

As a trusted Industrial Flange Gasket manufacturer and Industrial round gasket manufacturer, we integrate DuPont Kalrez technology for semiconductor and chemical processing applications. For technical data, request our Kalrez O-ring specification pdf. From Garlock Gasket to PHE Gasket and PTFE/ Teflon Gasket, CRI Gasket is your ultimate source for high-durability industrial round gasket and Round gasket solutions.

| Industrial FEP Encapsulated O-Ring Specifications | |

|---|---|

| Inner Diameter (ID) | 300 mm |

| Material Type | FEP Encapsulated Rubber Core |

| Primary Usage | Industrial Sealing & Chemical Processing |

| Shape | Round / Circular Section |

| Packaging Type | Standard Industrial Packet |

| Cross-Section Thickness | 10 mm |

Standard elastomer FEP-O-rings often suffer from chemical degradation when exposed to aggressive media or atmospheric gases, resulting in seal failure, hardening, or embrittlement. This is typically due to inadequate solvent resistance and restricted working temperature ranges.

In contrast, our encapsulated FEP-O-rings feature a seamless fluoropolymer jacket that prevents direct contact between the inner core and the process medium. The superior resin properties of the FEP jacket provide universal chemical resistance, making these seals suitable for the most demanding industrial applications and high-temperature environments.

| Industrial FEP Encapsulated O-Ring Specifications | |

|---|---|

| Inner Diameter (ID) | 300 mm |

| Material Type | FEP Encapsulated Rubber Core |

| Primary Usage | Industrial Sealing & Chemical Processing |

| Shape | Round / Circular Section |

| Packaging Type | Standard Industrial Packet |

| Cross-Section Thickness | 10 mm |

Traditional elastomer O-rings, such as standard Nitrile or Viton / FKM Gasket, often face chemical degradation when exposed to aggressive solvents or acids. To prevent hardening or seal failure, CRI Gasket provides high-performance FEP Encapsulated O-Rings. As a leading Industrial Flange Gasket manufacturer and Aflas O Ring Supplier, we combine a seamless FEP jacket with a high-rebound core to ensure Universal Chemical Resistance and Static Reliability.

Our FEP Encapsulated O-Rings outperform standard rubber seals in pressure vessels and heat exchangers. If you are looking for the FEP Encapsulated O-ring price or Encapsulated O-ring price in India, we offer competitive rates for Viton or Silicon Rubber cores. These seals are ideal for chemical pumps, offering Low Friction and a Superior Thermal Range where Garlock Gasket or PHE Gasket units require maximum protection.

As a trusted Industrial Flange Gasket exporter and Industrial round gasket manufacturer, we provide FEP and PFA Encapsulated solutions for pharmaceutical and petrochemical industries. Whether you need an industrial round gasket, Round gasket, or a specialized Teflon Gasket, our FEP Encapsulated range ensures zero-leakage performance. Download our Encapsulated O-ring specification pdf for more technical details.

| AFLAS O-Ring Quick Specs | |

|---|---|

| Material | AFLAS® (TFE/P) |

| Usage | Oil, Gas & Steam |

| Hardness | 70-90 Shore A |

| Temp. | Up to 200°C |

CRI Gasket is a premier Aflas Gasket Manufacturer and Aflas Gasket Supplier, providing elite sealing materials for extreme environments. As a leading Aflas O Ring Supplier and O-ring supplier, we offer custom dimensions and thicknesses that outperform standard rubber seals. Our Aflas (TFE/P) products are engineered for H2S resistance, steam resistance, and high-pressure oil & gas applications.

If you are looking for the best Aflas O-ring price or Aflas gasket price list in India, we provide cost-effective alternatives to FFKM with superior amine resistance and heat stability up to 200°C. From Industrial Flange Gasket needs to specialized PHE Gasket and Garlock Gasket units, our Aflas solutions ensure zero-leakage in chemical processing and downhole environments.

Whether you need a Viton / FKM Gasket or an Aflas O-ring, we are your trusted Industrial Flange Gasket manufacturer and Industrial Flange Gasket exporter. Request our Aflas Gasket specification pdf today for high-durability industrial round gasket and Round gasket requirements across India.

Key Benefits:

Get the durability and chemical makeup needed for high-stakes industrial applications with our AFLAS O-rings.