| Hoop Material | SS304, 316, 321 |

|---|---|

| Normal Thickness V-Shaped | 3.2 |

| Normal Thickness W-Shaped | 2.5 |

| Filler Material | Asbestos |

| Material | Stainless Steel |

| Inner, Outer Ring | Carbon Steel |

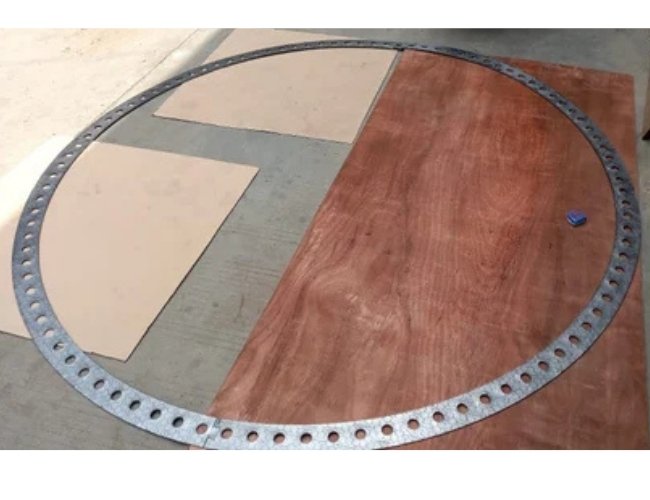

Spiral Wound Gasket (SWG) manufacturing is the primary expertise of CRI Gasket. As a leading Spiral Wound Gasket manufacturer and supplier in India , we specialize in high-precision sealing solutions designed for extreme environments. Every Spiral Wound Gasket in our 2026 range is engineered to withstand high thermal cycles and intense pressure surges. Our Spiral Wound Gasket construction features V-shaped metallic windings (SS304, SS316, SS321) combined with high-quality filler materials like Graphite, PTFE, or Mica. This unique spring-like action allows the Spiral Wound Gasket to maintain an airtight seal even in fluctuating conditions. Whether you need a standard Spiral Wound Gasket for pipelines or a custom-designed Spiral Wound Gasket for heat exchangers and boilers, our products ensure maximum safety and leak-proof performance in critical industrial applications."

| Thickness | 3 mm |

|---|---|

| Material | Asbestos |

| Usage/Application | Industrial |

| Shape | Rectangular |

| Pressure | Packet |

| Brand | CTR |

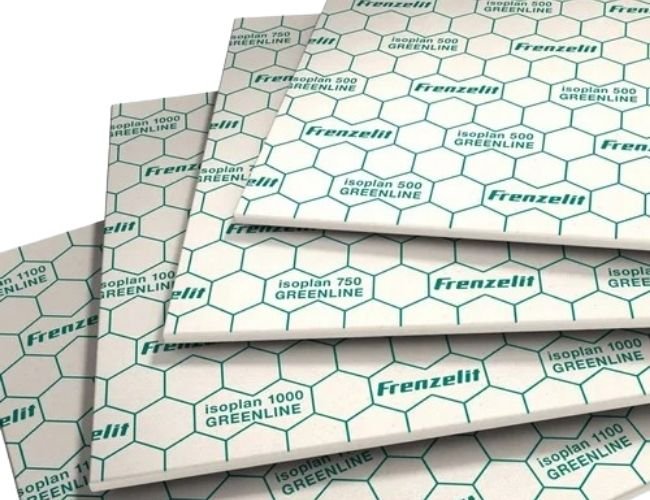

A Non Asbestos Gasket Sheet" is a flat, compressed sheet material used to create seals between two surfaces, designed as a safe alternative to asbestos gaskets, typically made from synthetic fibers like aramid (Kevlar), mineral fibers, and polymers, offering resistance to heat, pressure, and various chemicals depending on the specific application, while posing no health risks associated with asbestos exposure; it's commonly used in industrial machinery, automotive engines, and plumbing systems where a tight seal is required.

| Brand | CTR / Garlock Equivalent |

|---|---|

| Material | Non-Asbestos Fiber (CNAF) |

| Thickness | 3 mm |

| Shape | Rectangular / Custom Cut |

| Usage/Application | Industrial Chemical & Hydrocarbon Processing |

| Pressure Rating | High Pressure (Class 150/300 compatible) |

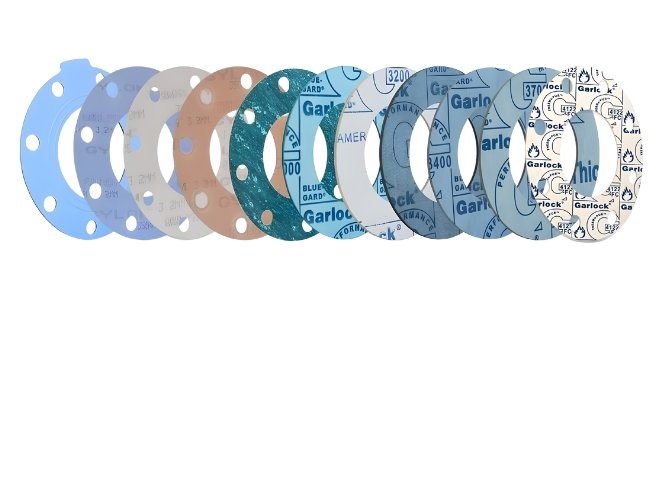

Garlock gasketing products are manufactured in completely modernized facilities. Tight quality controls are used to assure product conformance to specifications and uniformity, resulting in unvarying performance on the job.

Garlock is certified to ISO-9001 standards and is audited annually to ensure maximum reliability. Today’s environmental concerns demand positive seals; our gaskets provide that assurance across chemical processing, power generation, and transportation industries.

| Material | Stainless Steel |

|---|---|

| Thickness (in mm) | 1.5 mm |

| Usage/Application | Industrial |

| Color | Natural |

| Thickness | 4.5 mm |

| Sheet Size Available | NO |

Manufactured using a combination of stainless steel windings, filler materials like graphite, PTFE, and mica, our spiral wound gaskets deliver exceptional sealing efficiency. They are commonly used in flanges, heat exchangers, boilers, pipelines, reactors, valves, and high-pressure processing units.

| Thickness | 5 mm |

|---|---|

| Shape | Round |

| Usage/Application | Industrial |

| Packaging Type | Packet |

| Color | Brown |

| Material | Phlogopite Mica |

| Brand | CTR |

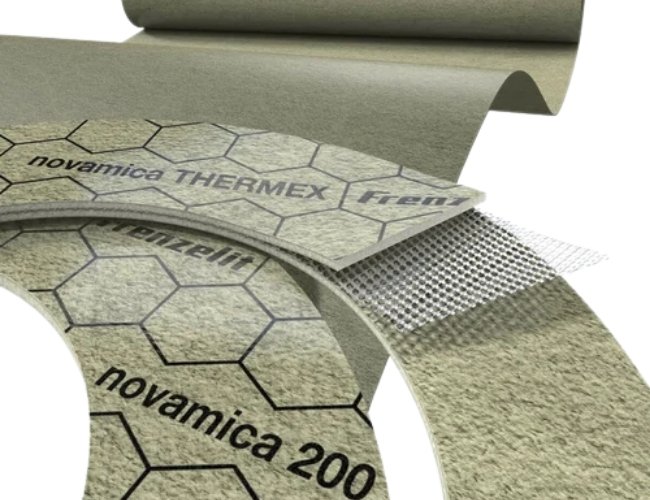

Frenzelit Novamica Thermax" refers to a high-temperature gasket material manufactured by Frenzelit, composed primarily of optimized phlogopite mica combined with a stainless steel expanded metal insert, allowing for exceptional sealing performance in extreme heat environments up to 1000°C, making it ideal for applications like exhaust systems, turbochargers, and industrial high-temperature processes; essentially, it provides excellent strength, handling properties, and long-term sealing capability due to the metal reinforcement within the mica matrix.